Ah, the frustration of a broken SUP paddle shaft or blade! We’ve all been there – eagerly heading out for a day of stand-up paddleboarding, only to discover that our trusty equipment has suffered a mishap.

But fear not, my friends, for we are here to guide you through fixing that broken paddle. In this article, we’ll share some expert tips and tricks to get your paddle back in working order, allowing you to once again glide effortlessly across the glistening water. So, gather your tools, and let’s embark on this paddle repair adventure together!

Assessing the Damage

Identifying the Type of Break

When faced with a broken SUP paddle, the first step is identifying the type of break. This will help determine the specific repair method needed and the materials required. Common breaks in SUP paddle shafts include fiberglass, carbon fiber, and wooden shafts. On the other hand, cracks in paddle blades can be found in fiberglass and carbon fiber blades. By closely examining the break, we can better understand the extent of the damage and proceed with the appropriate repair technique.

Determining the Severity of the Damage

After identifying the type of break, it is essential to determine the severity of the damage. The severity will dictate the course of action and whether a repair or replacement is necessary. For minor breaks, such as small cracks or chips, a repair might be sufficient. However, for severe breaks that compromise the structural integrity of the paddle or render it unsafe to use, a replacement might be the best solution. Carefully assessing the extent and location of the damage will help make an informed decision on how to proceed.

Inspecting the Materials Used

The materials used in constructing the SUP paddle shaft and blade are crucial in determining the repair process. Fiberglass shafts and blades are commonly used due to their durability and lightweight properties. Carbon fiber shafts and blades offer even greater strength and stiffness. Wooden shafts, although less common, provide a traditional, aesthetically pleasing option. By inspecting the materials used, we can choose the appropriate repair method and materials to ensure a successful fix and maintain the paddle’s performance.

Fixing a Broken SUP Paddle Shaft

Repairing a Fiberglass Shaft

To repair a fiberglass shaft, begin by cleaning the broken area using acetone or rubbing alcohol to remove any dirt or debris. Next, apply a fiberglass repair kit, which typically includes epoxy resin and fiberglass cloth. Cut the fiberglass cloth to size, ensuring it fully covers the break. Mix the epoxy resin according to the manufacturer’s instructions and apply it to the broken area. Lay the fiberglass cloth over the resin, ensuring it is fully saturated. Smooth out any air bubbles or excess resin with a brush or roller. Allow the repair to cure for the recommended time before testing the paddle.

Fixing a Carbon Fiber Shaft

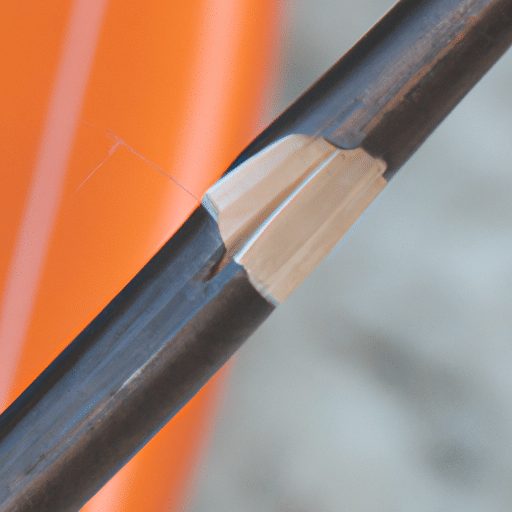

Repairing a carbon fiber shaft requires a similar process to fiberglass. Begin by cleaning the area thoroughly, removing any dirt or loose fibers. Next, sand the broken area lightly to create a rough surface for the repair adhesive to adhere to.

Apply a carbon fiber repair adhesive, following the manufacturer’s instructions and mixing ratios. Fill the break with the adhesive, completely covering the damaged section. Use a clean brush or cloth to smooth out the adhesive and remove any excess. Allow the repair to cure fully before using the paddle again.

Mending a Wooden Shaft

Repairing a wooden SUP paddle shaft requires a slightly different approach. Start by removing any loose or damaged wood around the break. Next, apply wood glue to the broken area, filling the gap. Clamp the shaft firmly and allow the glue to dry according to the manufacturer’s instructions. Once the glue has cured, sand down any rough edges or excess glue to achieve a smooth finish; finally, apply a wood sealant or varnish to protect the repaired area and maintain the integrity of the wooden shaft.

Repairing a Cracked SUP Paddle Blade

Assessing the Crack

When repairing a cracked SUP paddle blade, it is essential to assess the crack’s severity and location. If the crack is small and does not extend through the entire blade, a repair is possible. However, if the crack is large or compromises the blade’s structural integrity, a replacement blade might be necessary. By carefully inspecting the crack, we can determine the appropriate repair method and ensure the paddle remains safe and functional.

Repairing a Fiberglass Blade

To repair a fiberglass blade, clean the crack with acetone or rubbing alcohol to remove dirt or debris. Next, apply a fiberglass repair kit, which typically includes epoxy resin and fiberglass cloth. Cut the fiberglass cloth to size, ensuring it fully covers the crack. Mix the epoxy resin according to the manufacturer’s instructions and apply it to the crack. Lay the fiberglass cloth over the resin, ensuring it is fully saturated. Smooth out any air bubbles or excess resin with a brush or roller. Allow the repair to cure fully before testing the blade’s strength.

Fixing a Carbon Fiber Blade

Repairing a carbon fiber blade requires a similar process to fiberglass. Begin by cleaning the crack thoroughly, removing any dirt or loose fibers. Next, sand the cracked area lightly to create a rough surface for the repair adhesive to adhere to. Apply a carbon fiber repair adhesive, following the manufacturer’s instructions and mixing ratios. Fill the crack with the adhesive, completely covering the damaged section. Use a clean brush or cloth to smooth out the adhesive and remove any excess. Allow the repair to cure fully before using the blade.

Replacing a Damaged SUP Paddle Shaft

Measuring for Size and Fit

When replacing a damaged SUP paddle shaft, it is crucial to measure the existing shaft to ensure proper size and fit. Measure the length of the current shaft from the top to the blade’s connection point and note the diameter of the shaft. This information will help select a suitable replacement shaft and ensure compatibility with the existing paddle blade. Taking accurate measurements guarantees a seamless replacement process and optimal performance.

Choosing the Right Shaft Material

Selecting the proper shaft material is crucial when replacing a damaged SUP paddle shaft. Consider factors such as durability, weight, and personal preferences. Fiberglass shafts balance strength and weight, making them a popular choice. Carbon fiber shafts enhance stiffness and lightness, ideal for those seeking optimal performance. Wooden shafts offer a more traditional look and feel. Weighing the pros and cons of each material will help you make an informed decision and select the suitable shaft material for your needs.

Replacing the Shaft

Replacing a damaged SUP paddle shaft entails removing the old shaft and installing the new one. Begin by detaching the blade from the old shaft, following the manufacturer’s instructions. Next, carefully remove the handle and any other connectors. Align the new shaft with the existing blade and handle, ensuring a secure fit. Follow the manufacturer’s guidelines for assembly and use any necessary tools to tighten the connections securely. Once the replacements are complete, test the paddle to ensure it functions properly and feels comfortable.

Replacing a Damaged SUP Paddle Blade

Finding a Suitable Replacement Blade

When replacing a damaged SUP paddle blade, it is essential to find a suitable replacement that matches the existing shaft and fits your paddling style. Consider the blade’s size, shape, and materials to ensure compatibility. Consider power, efficiency, and maneuverability when selecting a replacement blade. Many paddle manufacturers offer a range of blade options to suit different needs and preferences. Research and consult with experts or your local paddle shop to find the perfect replacement blade for your SUP paddle.

Aligning and Attaching the Replacement Blade

Once you have found a suitable replacement blade, aligning and attaching it to the paddle shaft is the next step. Begin by removing the old blade, following the manufacturer’s instructions. Clean the shaft connection point thoroughly to remove any debris or residue. Align the new blade with the shaft, ensuring they are in the correct orientation. Follow the manufacturer’s guidelines for assembly, which may involve sliding the blade onto the shaft or using screws or connectors. Tighten the connections securely to ensure the blade is firmly attached.

Testing the New Blade

After replacing the damaged SUP paddle blade, it is crucial to test the new blade and ensure it performs as expected. Take the newly assembled paddle out for a test paddle, paying attention to any differences in power, responsiveness, or comfort. Adjust your technique if necessary to accommodate variations in the new blade’s design. Testing the new blade allows you to familiarize yourself with its characteristics and make any necessary adjustments to optimize your paddling experience.

Preventing Damage to Your SUP Paddle

Using Paddle Blade Covers

One effective way to prevent damage to your SUP paddle is using paddle blade covers. These covers protect during transport and storage, preventing scratches, dings, and other forms of damage. Paddle blade covers are typically made from durable materials such as neoprene or nylon and feature a snug fit to keep the blades secure. Using blade covers not only safeguards your paddle but also prolongs its lifespan, ensuring it remains in optimal condition for your future paddling adventures.

Avoiding Excessive Force or Impact

To prevent damage to your SUP paddle, it is crucial to avoid subjecting it to excessive force or impact. While paddling, be mindful of rocks, shallow water, and other potential hazards that may cause sudden impacts. Try to maintain a smooth and controlled stroke, avoiding unnecessary strain on the paddle. Additionally, avoid using your paddle as a lever or pry tool, as this can lead to breakage or damage. By treating your paddle with care and avoiding unnecessary force or impact, you can significantly reduce the risk of damage and prolong its lifespan.

Proper Storage and Transportation

Proper storage and transportation are vital in preventing damage to your SUP paddle. When not in use, store your paddle in a secure and dry location away from extreme temperatures or direct sunlight. Avoid leaning or stacking heavy objects on the paddle, which can cause damage. During transportation, secure the paddle properly with straps or a paddle bag to prevent it from moving around or getting scratched. By paying attention to proper storage and transportation practices, you can protect your SUP paddle from unnecessary wear and tear.

Seeking Professional Assistance

When to Call a Professional

While many SUP paddle repairs and replacements can be done independently, there may be instances when it is best to seek professional assistance. If you are unsure of your repair skills, the severity of the damage, or lack the necessary tools, it is advisable to consult a professional. Likewise, for complex repairs or replacements involving advanced materials such as carbon fiber, a professional’s expertise may be necessary to ensure a proper and long-lasting fix. Knowing your limitations and when to call a professional will help prevent further damage and guarantee a reliable repair job.

Choosing a Reliable Repair Service

When seeking professional assistance for your SUP paddle repair or replacement, it is essential to choose a reliable repair service. Look for repair shops or technicians with extensive experience in paddle repair and a good reputation within the paddling community. Ask for recommendations from fellow paddlers or consult online reviews to ensure you select a reputable and trustworthy repair service. Additionally, inquire about their repair processes, warranties offered, and turnaround times to ensure a smooth repair experience.

Considering Warranty Options

Before proceeding with a repair or replacement, it is essential to consider any warranty options available for your SUP paddle. Many paddle manufacturers offer warranties that cover defects in materials or artistry. However, it is essential to note that warranties generally do not cover damage caused by user error or accidents. Review the terms and conditions of your paddle’s warranty and contact the manufacturer if your damage falls under their coverage. Understanding your warranty options can help you make an informed decision on how to proceed with the repair or replacement.

Maintaining and Extending the Lifespan of Your SUP Paddle

Regular Inspection and Maintenance

To maintain and extend the lifespan of your SUP paddle, regular inspection and maintenance are essential. Routinely inspect your paddle for any signs of damage, such as cracks, chips, or loose connections. If any issues are detected, address them promptly to prevent further damage. Additionally, clean your paddle after each use, removing any dirt, salt, or debris that may have accumulated. Proper maintenance practices, such as tightening screws, replacing worn components, and lubricating moving parts, will ensure your paddle remains in optimal condition for years.

Cleaning and Care Tips

Cleaning your SUP paddle properly is crucial to maintain its performance and longevity. After each use, rinse the paddle with fresh water to remove salt, sand, or other debris. Use a mild detergent or paddle cleaner to remove stubborn dirt or stains, following the manufacturer’s instructions. Avoid using harsh chemicals or abrasive materials that can damage the paddle’s finish. Additionally, store your paddle in a dry and clean environment to prevent moisture buildup or mold growth. By following these cleaning and care tips, you will keep your paddle in pristine condition and ready for your next adventure.

Proper Handling and Usage Techniques

Proper handling and usage techniques are integral to extending the lifespan of your SUP paddle. When handling the paddle, avoid excessive bending or twisting, as this can cause stress on the shaft or blade. Use the paddle within its intended limits, avoiding excessive force or impacts that may lead to damage. Pay attention to proper paddle placement and technique to maximize efficiency and minimize strain on the paddle. By adopting proper handling and usage techniques, you can ensure the longevity and performance of your SUP paddle.

Safety Considerations

Using Protective Gloves and Eyewear

When repairing or replacing a SUP paddle shaft or blade, it is essential to prioritize safety. Wear protective gloves to prevent injury from sharp edges or hazardous chemicals used in the repair process. Additionally, consider using protective eyewear to shield your eyes from debris or chemicals. Safety should always be a top priority when working on a SUP paddle to prevent accidents or further damage.

Working in a Well-Ventilated Area

Working in a well-ventilated area is crucial when conducting repairs or replacements on a SUP paddle. Many repair materials, such as epoxy resin or adhesives, emit fumes that can be harmful if inhaled in large quantities. Ensure proper airflow and adequate ventilation to minimize exposure to these fumes. If working indoors, consider opening windows or using fans to promote air circulation. By working in a well-ventilated area, you can protect your health and ensure a safe repair process.

Following Manufacturer Guidelines

When repairing, replacing, or maintaining a SUP paddle, it is essential to follow the manufacturer’s guidelines. Manufacturers provide specific instructions and recommendations for repairs, replacements, and maintenance, ensuring optimal performance and safety. Familiarize yourself with the manufacturer’s guidelines and adhere to them closely to avoid voiding warranties or compromising the paddle’s integrity. By following the manufacturer’s instructions, you can ensure a reliable and safe repair or maintenance process.

Conclusion

Final Thoughts

Repairing or replacing a broken SUP paddle shaft or blade may seem daunting initially, but with the proper knowledge and tools, it can be a manageable process. Assessing the damage, determining the severity, and inspecting the materials used are the initial steps to take. From there, specific repair or replacement techniques can be employed, depending on the materials and nature of the damage. Following safety considerations, such as using protective gear and working in a well-ventilated area, is crucial to prevent accidents and injuries.

Remembering to Prioritize Safety

Throughout the repair or replacement process, it is essential to prioritize safety. Wearing protective gloves and eyewear, working in a well-ventilated area, and following manufacturer guidelines are all crucial steps to ensure a safe repair or replacement process. Never hesitate to seek professional assistance if unsure or if the damage is severe. Prioritizing safety ensures not only the well-being of the repairer but also guarantees a reliable and long-lasting SUP paddle.

Enjoying a Reliable SUP Paddle

By adequately assessing, repairing, and maintaining your SUP paddle, you can enjoy years of reliable paddling adventures. Regular inspection, cleaning, and care, along with proper handling and usage techniques, will help extend the lifespan of your paddle and ensure optimal performance.

When repairs or replacements are necessary, following the appropriate techniques and materials for the specific type of damage will result in a successful fix. With a well-maintained and functional SUP paddle, you can continue exploring the waters with confidence and enjoyment.